Direct-to-garment (DTG) printing is gaining popularity as an efficient and versatile way to produce custom apparel. It is capable of high-resolution, full-color printing directly on a variety of fabrics, including cotton, polyester, blended fabrics, etc. Compared with traditional printing methods, DTG printing brings greater flexibility and is ideal for small-batch production and custom orders.

When considering investing in a DTG printer, you need to understand the associated costs, such as the price of the printer itself, consumables consumption, maintenance, power consumption, etc. All of these factors will affect long-term operating costs, so you need to know them before you buy. This comprehensive guide will analyze expenses from the initial investment to ongoing operating costs to help you make an informed decision.

DTG printing is expanding rapidly due to its ability to provide users with flexible and cost-effective solutions to meet consumer demand for customized products.

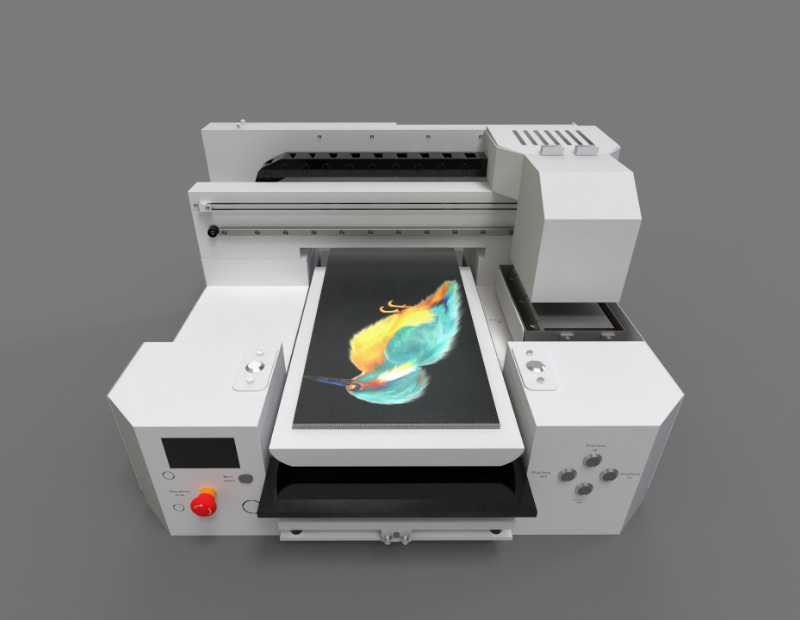

Direct-to-garment (DTG) printing is a method of printing patterns directly onto a wide range of textiles (including T-shirts, hoodies, pants, hats, etc.) using specialized inkjet technology. Its advantage is that it can not only perfectly present the fine details of the pattern, but also present a rich and colorful color effect.

Moreover, unlike traditional screen printing methods, DTG printing does not require a separate screen for each color, greatly reducing preparation time and production costs. DTG printing is particularly suitable for small series production and custom orders, which can quickly respond to market demands and personalized consumer preferences.

DTG printing is becoming more and more popular in the industry because they have many advantages that make it an important technology choice in modern textile printing.

High Quality: Thanks to advanced inkjet technology, DTG printing produces vivid and detailed prints that perfectly reproduce the details and colors of patterns. This high-quality printing can well meet the high standard of printing quality requirements.

Flexibility: As we mentioned earlier, unlike traditional printing methods, DTG printing does not need plate making and a complex preparation process. Therefore, it can be flexibly adjusted according to demand, which can well meet the personalized and diversified market needs.

Ease of Use: The direct-to-garment printer is super simple to operate. For example, Incolorprint DTG Printer, the interface design is particularly user-friendly, and there are many automation functions, even those who have not learned printing can easily get started. This not only reduces training costs, but also improves production efficiency.

Quick Turnaround: Compared to traditional printing methods, DTG printing reduces the time needed to go from design to finished product because it does not require the complex plate making and debugging process that traditional printing does. Therefore, it can speed up production and respond more flexibly to rapidly changing market demands.

When purchasing a DTG printer, there are numerous things to take into account, and one of the most important ones is the initial cost. The printer itself, necessary accessories and add-ons, and software are all included in the initial cost.

The printer itself is the most significant upfront expense. There are a wide variety of DTG printers on the market, and their prices vary widely based on features, print quality, speed, and intended use. Here we introduce three types of printers:

Entry-Level Printers: Generally, they sell for $10,000 to $20,000. These printers can handle simple designs and small order volumes. They have basic printing capabilities. They are easy to use, maintain, and configure. These printers are better suited for startups or small enterprises.

Mid-Range Printers: The price is between $20,000 and $50,000. Compared to entry-level printers, these printers have more functions and can print faster and with higher quality. They can handle medium-sized orders, are appropriate for medium-sized businesses, and offer better print quality and production efficiency.

High-End Printers: Cost up to $50,000 and designed for mass production, high-end printers are usually equipped with the most advanced technology and the highest printing accuracy, able to complete a large number of high-quality printing tasks in a short time. These printers can handle the demands of high-volume, high-quality production and are ideal for large businesses that need to print fine text frequently.

To ensure efficient operation and high-quality output in the DTG printing process, some necessary accessories and add-ons are essential in addition to the printer itself.

Pre-Treatment Machine: This is an important accessory for DTG printing. It is used to pretreat fabrics (especially dark fabrics) before printing, ensuring that the ink can firmly adhere to the fabric. Costs range from $1,000 to $5,000, depending on the functionality and performance of the device.

Heat Press: Used to cure the printed pattern and ensure that the pattern adheres firmly to the fabric. The cost of a heat press can vary from $500 to $3,000, based on the model and features.

Drying Rack or Conveyor Dryer: Essential for large operations and fast drying of printed matter. Depending on the kind of equipment and processing capacity, drying equipment might cost between $1,000 and $10,000.

Most DTG printers come with some basic software to meet everyday printing needs. But if you want to better control the production, color calibration, and design processes, you need to buy some advanced software, which usually needs additional expenses.

These integrated software packages, which usually range in price from $500 to $2,000, require an investment but can greatly increase the company’s competitiveness and responsiveness, increasing the assurance of the final product’s quality and consistency. Businesses looking to expand their DTG printing operations will find that this investment is well worth it.

In addition to the initial investment, the operating costs of DTG’s printing business are also an important factor affecting overall profitability. These costs include ink and consumables, maintenance and repairs, power consumption, and labor costs.

In the DTG printing process, ink and other consumables are a large part of the operating costs.

Ink Costs: DTG printers use advanced textile inks, which are more expensive than traditional printing inks. However, the performance and printing quality it provides are unmatched by traditional inks. For different printing tasks, the consumption of ink is also different. For example, when printing complex multi-color designs and large-area printing, more ink will be consumed, and the corresponding cost will increase. In general, the average price of ink used by DTG printers is about $200 to $300 per liter.

Pre-Treatment Solution: When printing dark fabrics, a pre-treatment solution is needed to ensure that the ink will adhere to the fabric. It costs about $50 to $100 a gallon and varies in price depending on the brand and quality. Of course, a high-quality pre-treatment solution will cost more, but it can be a good way to ensure the quality and durability of the print, thereby reducing rework and material waste.

Cleaning Supplies: Regular cleaning and maintenance are essential to ensure that DTG printers are always in top print condition. It needs to purchase the required cleaning supplies, such as cleaning fluids, rags, and other daily maintenance supplies, which probably will take 50 to 100 dollars a month.

To ensure that the DTG printer is always in top condition, regular maintenance is required. This includes routine maintenance, regular replacement parts, and professional services.

Routine Maintenance: Includes cleaning and calibrating the printer. This requires employees to receive basic maintenance training to ensure they can properly operate and maintain the equipment. Through routine maintenance, equipment failures and downtime can be effectively reduced and production efficiency can be improved.

Replacement Parts: Over time, parts such as print heads and shock absorbers may need to be replaced. Because the wear and aging of these parts will affect the print quality and equipment performance, timely replacement is necessary. The cost of replacing these parts can range from $100 to $1,000, depending on the type and brand of the part.

Professional Servicing: Although routine maintenance can reduce the occurrence of most failures, professional repairs and inspections may still be required. Professional repairs can cost between $500 and $1,500 per year, depending on the complexity and frequency of the repairs.

DTG printers consume a lot of power during operation, especially in the case of high loads and continuous production. In addition to the printer itself, related equipment such as preprocessors, hot presses and drying equipment can also significantly increase power consumption.

Monthly electricity charges vary based on the frequency of use of the equipment, the size of the operation and local electricity prices. In general, monthly electricity bills for DTG printing operations range from $50 to $200. Efficient energy management, such as selecting efficient and low-energy printers and optimizing the printing process, can help reduce operating costs and improve the overall efficiency of the business.

When running a small business, labor costs are a key factor in DTG printing operations. It includes not only the salary of the staff to manage the printing process, but also the time and labor required for design, pre-processing, and post-processing.

Effective management of labor costs can help businesses improve efficiency and profitability. It can improve the operational skills and efficiency of employees through training, or introduce automation equipment and optimize workflow to improve production efficiency and reduce labor costs.

Aside from the apparent expenditures, there are a few other hidden costs related to DTG printing that should be taken into account when calculating the total operational costs.

Downtime due to maintenance, repair, or training can significantly impact productivity, which directly impacts productivity. The impact of downtime can vary depending on the reliability of the printer and the efficiency of the maintenance process.

Businesses can take a number of actions to lessen the damage that comes from downtime. Create a productive maintenance plan first. For example, to lessen the impact on production, schedule maintenance for off-peak or off-season times. Second, keep regular replacement parts on hand for expedited replacement and reduced maintenance duration. Third, alternate training of employees to ensure that skilled operators are always available.

When it comes to DTG printing technology, it does require a certain learning curve. Employees need time to master new technologies and familiarize themselves with the operation of equipment. In order to maximize printer functionality and reduce errors, it is very important to invest in training.

Training costs generally range from $500 to $2,000. Employees may be less productive during training, which is also a hidden time cost. However, through systematic and structured training programs, employees can quickly master skills, reduce operational errors, and improve production efficiency.

For best printing results, DTG printers need a controlled environment that includes enough space, ventilation, temperature and humidity control.

DTG printers need a specific amount of workspace, so there may be additional costs associated with purchasing or renting an appropriate workspace. It could be essential to install or update the ventilation system, which also requires a certain cost, to guarantee the security and comfort of the working environment.

In order to maintain print quality and equipment life, DTG printers also require specific temperature and humidity conditions. Investing in HVAC systems or other environmental control equipment is another hidden expense.

DTG printers come in a lot of different models, and their costs differ as well. To assist you in selecting the printer that best meets your needs, we have provided a detailed comparison of the various printer levels below.

Examples: Incolorprint C5 A3, Epson SureColor F2100, Brother GTXpro B

Initial Cost: Generally speaking, entry-level printers cost between $10,000 and $20,000. For individuals on a tight budget or small organizations, they are a cost-effective choice.

Operational Costs: Also, entry-level printers have comparatively cheap operational expenses. They are more cost-effective in daily operations since they require less ink and require less maintenance than high-end models.

Best For: Their price/performance ratio and basic printing features make them the perfect choice for small businesses, start-ups, and hobbyists. These printers have comparatively low production speeds and quality, but they are still enough for small-scale production and customized orders.

Examples: Incolorprint C8 Pro A2, Ricoh Ri 2000, DTG M2

Initial Cost: Mid-range printers typically cost between $20,000 and $50,000. These printers print with greater quality and at faster speeds. They are a wise option if you want to grow your company’s production capacity.

Operational Costs: Because mid-range printers require more complicated ink and maintenance than entry-level printers, operational expenses will be a bit higher. However, they provide better printing accuracy and quicker production speeds.

Best For: They are perfect for medium-sized companies who want to increase their production capacity. Mid-range printers can handle larger order volumes and provide higher production efficiency and better print quality.

Examples: Incolorprint C11 / C11+ Max A1, Kornit Avalanche HD6, Epson SureColor F3070

Initial Cost: High-end printers will cost more, at $50,000 and up. High-end models use advanced DTG printing technology, with the most advanced functions and the highest production capacity.

Operational Costs: Due to the advanced features and higher production volumes of high-end printers, operating costs are the highest of the three models. This includes high ink consumption, frequent maintenance needs, and possible professional service costs. However, their unparalleled print quality and speed make them ideal for large-scale manufacturing.

Best For: They are ideal for large production companies or those with a large number of custom order requirements, able to cope with large-scale, high-quality production requirements. Companies that customize order requirements are able to cope with large-scale, high-quality production requirements.

Cost-benefit analysis is a key step when choosing a DTG printer. This can help companies assess the rationale of the initial investment and also predict future benefits and costs to make more informed choices.

Calculating the return on investment of a DTG printer requires a combination of initial investment and ongoing costs, as well as potential revenue.

Initial Investment: There is no doubt that the price of the DTG printer itself is the largest initial cost, and different models have different prices. Then there are the accessories and consumables they need, the cost of software, setup, etc., all need to be taken into account.

Ongoing Costs: Ink is a large part of ongoing costs in the operation of a DTG printer. Moreover, especially the use of special ink, so the price is higher than ordinary ink. You also need to carry out regular maintenance and repair of the printer, the electricity consumed, and the required labor, all need a certain cost.

Revenue: Income is determined according to your print volume, the larger the print volume, the higher the income potential. Of course, it is also necessary to consider market competition, materials, customer needs, and other aspects of pricing.

Monthly Profit = Monthly Revenue – Monthly Operating Costs

Payback Period = Initial Costs/Monthly Profit

Through this calculation, enterprises can clearly see the income after investing in DTG printers. If the ROI is high, the investment is worth it. If ROI is low, you need to rethink your marketing strategy or cost management.

With the continuous development of technology and market, DTG printer costs are also changing. Below we look at three future trends that will affect the cost of DTG printers.

The advancement of technology will be one of the main factors affecting the cost of DTG printers. Advanced technology can not only improve efficiency and production, but also reduce operating costs.

Automation: With the development of automation technology, DTG printers are becoming more and more automated. This can not only improve production efficiency and reduce labor costs, but also ensure better print quality.

Faster Print Heads: Print head technology is getting better and faster. Printing speed is faster, more orders can be completed in the same time, and production capacity is increased. In addition, improvements in print head technology may also reduce ink consumption, thus reducing operating costs.

Eco-Friendly Inks: As people pay more and more attention to environmental protection, the development of sustainable inks has become more and more important. Using environmentally friendly ink not only complies with market demands and environmental requirements, but it may also draw in more environmentally conscious customers and grow market share.

Market dynamics are also important factors affecting the cost of DTG printers. Changes in the market will directly affect the price of equipment and consumables.

Competition: The rivalry will get more fierce as more manufacturers enter the DTG printer market. As a result, the cost of DTG printers may go down, making them more affordable for more businesses, and the market will grow.

Global Supply Chain: Changes to the global supply chain will affect the availability and price of printer parts and consumables. For example, once transportation costs rise, the price of parts and consumables will rise. Companies need to be responsive to such changes and quickly develop procurement strategies.

With the emphasis on sustainable development, environmental innovation plays an important role in the future development of DTG printers. Apart from the reduced impact on the environment, the use of environmentally friendly technologies can also bring cost benefits.

Recycled Materials: The use of recycled materials in the printer manufacturing process can reduce the impact on the environment. Moreover, it’s normally cheaper to use recycled materials, so manufacturers can cut their costs of production in this way.

Energy Efficiency: The development of energy-saving technologies can lower DTG printer power costs. For instance, integrating energy-efficient energy management systems and low-consumption parts into a digital printer can lower electricity costs and improve economic efficiency.

When understanding the cost of DTG printers, it is not only the price of the printer itself, but also the operating costs such as ink, consumables, maintenance, electricity, and labor. There are also hidden costs such as training, downtime, environmental requirements, etc. By carefully analyzing the various costs and then comparing different levels of DTG printers, you can choose the one that suits you best.

With the development of technology, future DTG printers will be more automated and efficient, which can greatly reduce operating costs. Advanced DTG printers will make enterprises more competitive in the market. Because they can improve production efficiency, the return on investment will be better, which is conducive to the development of enterprises.

Incolorprint is committed to providing DTG printing solutions with high quality and low operating costs. Our printers are equipped with advanced automation technology that not only reduces the consumption of ink and consumables, but also has an automatic maintenance system. Choosing Incolorprint DTG printers can not only optimize current operating costs, but also gain an advantage in the highly competitive market.

CONTACT US

Guangzhou Yincai Intelligent Technology Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us